Virtual fence (VF) is a management tool that uses invisible barriers, established using Global Positioning System (GPS) coordinates, that influence livestock movement with a combination of auditory and electrical cues. A VF system includes the following elements: (1) a software interface to draw VF lines and the boundary zone on a digital map, which defines the grazing area and exclusion zone; (2) a GPS- enabled collar fitted around the circumference of an animal’s neck or other wearable device that contains technology to track livestock movement and deliver auditory and electrical cues to influence or limit livestock distribution; and (3) base stations and/or cellular signal to transmit and receive communication between the software and wearable device (Antaya et al., 2024a; Ehlert et al., 2024). In this fact sheet, we will provide an overview of the components that make up a VF collar. Then, we will focus on collar deployment, the process to prepare for collaring events, and suggest strategies to safely place VF collars on livestock while ensuring proper fit.

This publication is part of the Foundations of Virtual Fencing series. Other titles in this series include:

Collar components

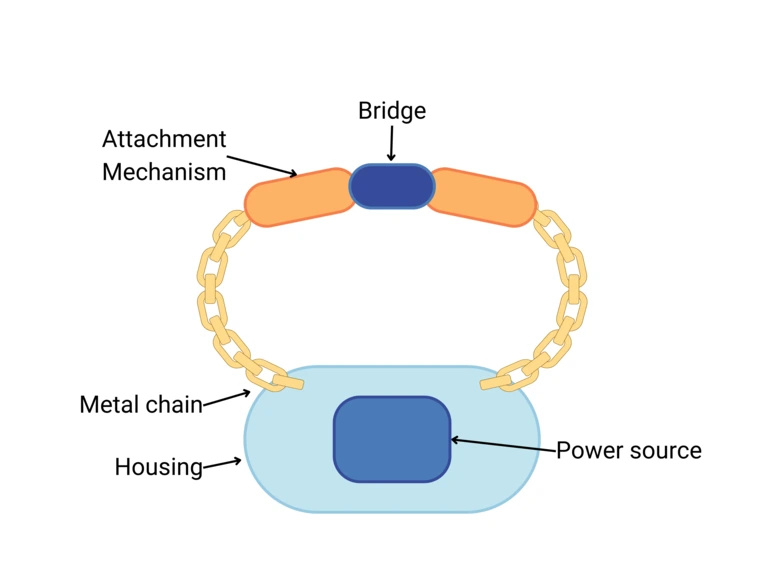

While the collar designs vary between VF vendors (Table 1), most collars generally include a collar housing, metal chains or belt-like straps, a bridge or strap, and an attachment mechanism (Figure 1). The collar housing contains VF electronics and a battery, either single-use and non-rechargeable or rechargeable with solar panels. Some designs include a battery door that must be opened and screwed on to replace non-rechargeable batteries. Other vendors have opted for rechargeable solar-charged batteries. To attach the collars to the animals, some vendors use metal chains connected to each side of the collar housing, which deliver electrical cues. Others use a belt-like design and the electrical cue is delivered via electrodes. A bridge or strap is used as a breakaway point mechanism for animal safety in case they get caught on vegetation, fences, corrals, or other hazards. The specific breakaway point and the force needed to break a collar differs for each vendor. The bridge or strap is necessary for the technology to be able to deliver the electrical cue. The attachment mechanism connects either side of the bridge to the separate sides of the metal chain (if applicable). Attachment mechanisms may be impacted by weather, type of vegetation, and other factors. It is important to talk to the VF vendor about the specific type of attachment mechanism and environmental conditions of the ranch to ensure proper attachment of collars and to prevent voiding the vendor's warranty.

Table 1. Collar designs vary depending on the VF vendor. They generally include collar housing, metal chains, a bridge, and an attachment mechanism. However, the breakaway point is designed differently for each company and some companies use a belt-like design for their collars. All collars include some breakaway point for animal safety.

| eShepherd™ from Gallagher™ | Halter™ | Nofence™ | Vence™ from Merck Animal Health | |

|---|---|---|---|---|

| Housing Stores battery/technology | Yes | Yes | Yes | Yes |

| Metal chains Helps deliver electrical cue | Yes | No | Yes | Yes |

| Belt-like design Helps deliver electrical cue | No | Yes | No | No |

| Bridge or strap Breakaway point | Yes | Yes | Yes | Yes |

| Attachment mechanism Connects two ends of the collar strap | Yes | Yes | Yes | Yes |

Figure 1. Stylized generic VF collar showcasing attachment mechanism, a bridge, metal chains, collar housing, and power source (either non-rechargeable battery or solar rechargeable battery). The specific design will vary by vendor and model. Some designs use a belt rather than metal chains and a bridge. All collars include a breakaway mechanism for animal safety.

Amber Dalke, University of Arizona

Preparing to collar

Based on field trials at the Santa Rita Experimental Range (SRER) in Green Valley, Arizona; planning is important to ensure that collar preparation and placement are efficient and safe. Specifics of collar preparation will vary with the VF system used and the size of the herd to be collared.

To prepare the collars for deployment, some vendors require opening the battery cover, installing the battery into the collar housing, screwing the battery cover closed, and labeling the collar housing; all of which can take a substantial amount of time. It takes about 2-3 minutes per collar, which adds up quickly for hundreds of collars. Other vendors require the batteries to be charged in a wall outlet prior to deploying collars like typical hand-held power tool batteries. And other vendors require the batteries to be charged in the sun before deploying the collars. This type of charging will take hours.

It is important to investigate the specific collaring deployment requirements for each VF company before collaring animals. Assemble all necessary tools and collar components prior to the collaring event. A collar inventory is recommended to make sure to have enough collars if there is a change in herd size. This will help save time and frustration on the day of the collaring event. Follow the vendor’s recommendations.

Collaring or removing a collar from an animal requires a proper animal handling facility. Using a facility that has corrals, a lane, and a squeeze chute with a head catch and neck bar (if available) is recommended. A portable hydraulic squeeze chute may further improve human and animal safety outcomes. Before starting a collaring event, check that the animal handling facility is in proper working order to avoid injuries and delays during collaring. Additionally, check gates, water systems, fences, and corrals for any objects that might cause a collar to get caught once the animal leaves the squeeze chute.

There are other considerations that should be well- thought-out before a collaring event as careful planning may improve outcomes for people and animals as well as overall success with VF. When planning a collaring event or replacing batteries (if required), it is important to review grazing management plans and the timing of the grazing rotation to ensure access to proper working facilities as outlined above. Ideally, collaring events can be paired with other livestock management tasks, such as pregnancy checks. Collaring may also add stress to the animals. Check the weather forecast prior to collaring to avoid handling livestock during extreme heat and reduce the likelihood of collaring in the rain, because this may allow moisture to enter the collar’s electronics, depending on the collar design.

When collaring for the first time, try to recruit someone with previous experience to help. If that is not possible, carefully review the training materials from the VF vendor and available tutorial videos. Practicing on a few animals before collaring the entire herd is also recommended. This will help prepare the team to be more efficient at collaring the entire herd.

Additionally, it may be helpful to gather the herd the day prior to the collaring event to reduce overall handling time, avoid unnecessary stress on livestock, prevent collaring after sunset, or the need for an unplanned additional day. Moreover, if the herd is already gathered, collaring can be done in the morning to avoid the heat of the day if squeeze chute facilities are not in the shade. If you do plan on gathering the herd ahead of time, you need to make sure that they have access to feed and water while waiting to be collared.

In the event of re-collaring, depending on the VF company, allow extra time for replacing non-rechargeable batteries or for charging batteries if there are no extra charged batteries on hand. If battery replacement or recharging is required, it may require more than one day to re-collar the herd. It may also be wise to have extra attachment mechanisms on hand in case some of them show signs of significant wear and tear. It would also be a good time to check collar fit and adjust as needed.

Collaring livestock

Putting collars on any animal can be dangerous and should be done with caution, especially when it is the first time for the people or animals involved. To safely collar an animal, we recommend using a squeeze chute. Sometimes, animals do not stay still and might go down in the chute. This can potentially cause a choking risk to the livestock and require the workforce to kneel to collar the animals. It is generally a good idea to have two people collaring, with one person on each side of the animal. One person can hand ends of the collar to the other person by going over and under the animal’s neck to help reduce stress for the animal. The other person can attach the collar. An animal will likely be very reactive if the collar is passed in front of its head, which may add stress to the animal during collaring and increase the risk that the animal tries to buck in the squeeze cute or swings its head. This can lead to injuries for the people handling the collar and the livestock; which could slow or delay the collaring process. Avoid leaning or standing over the animal when putting the collar on.

The animal can have sudden head movements that can hit the person collaring. It is recommended to use low-stress handling methods when collaring cattle (Stookey, J. M., and Watts, J. M., 2014). Try to avoid circumstances where hands or fingers may get caught in the collar or the chute or smashed against them if the animal makes a sudden movement. If the collar is dropped, carefully pick it up while avoiding the animal’s head and legs. Avoid standing in the path of travel when the animals are released from the squeeze chute. Each animal reacts differently to the VF collar, but animals are likely to buck when they come out of the chute if it is the first time they have a collar around their neck. This is a common reaction by livestock when they have an unknown object around their neck and does not mean that the collar is incorrectly fitted. Always have additional attachment mechanisms on hand in case one is lost or faulty.

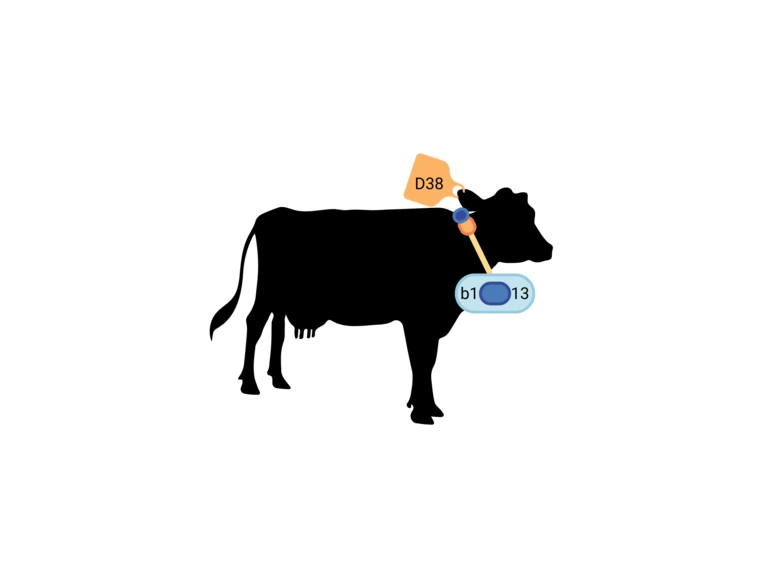

Figure 2. The animal’s unique ear tag number (D38) should be paired with the collar’s unique identification number (b113) in the VF system’s software whenever possible.

During collaring, it is a good practice to record information about each animal such as the collar identification number and animal identification information so that managers can determine if there are issues with specific animals as the system is implemented. It is also a good opportunity to record information about the disposition, age (if possible), Body Condition Score (BCS), and pregnancy status of each animal. A collar labeled with large letters and numbers using a permanent marker or paint can also help ensure that the collar can be identified from a distance and can help distinguish the collar if the vendor’s markings fade from wear and tear or environmental conditions. Two coats of ink or paint may increase the longevity of the markings, but it may still need to be reapplied every six months depending on the environment. The collar’s unique identification number can be paired with an animal’s unique identification number (e.g., ear tag number, Electronic Identification number - EID) in the VF software (Figure 2), which can be important for collar management (Antaya et al., 2024b). This technique might not be applicable for all the VF companies because some of them have large ID numbers, or a light/ sound to identify a specific collar.

Proper fit

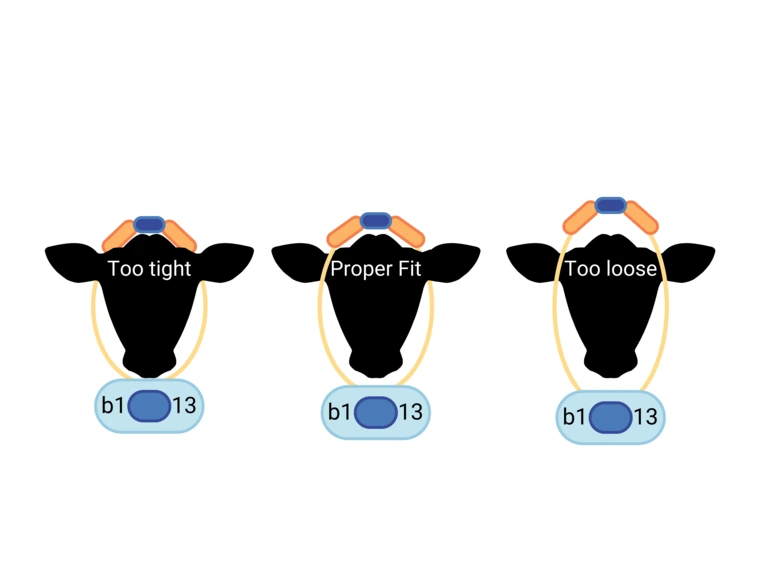

Proper fit is achieved when livestock can express their natural behavior without the collars interfering or falling off. Most VF companies provide some guidance on proper collar fit. Follow the vendor’s recommendations as there might be differences due to collar design. Generally, proper fit is achieved when a few fingers or fist (depending on the handler’s hand size) can be placed between the collar and the animal’s neck. For some VF companies, to test the fit, a collar can be pulled to the top of the animal’s head until it struggles to go over one ear. If it can be pulled over both ears, the collar is too loose (Figure 3).

There are several issues if the collar is too loose. Animals may accidentally get their front leg caught in the collar or the collar may just fall off the head of the animal and become useless until recovered and placed back on the animal. When part of the herd is no longer managed by VF, the unmanaged animals may impact management objectives by attracting collared animals into undesired areas because of their social hierarchy (Keshavarzi et al., 2020; Mayer et al, 2024b). It also takes time and money to find and retrieve collars and re-collar animals and there may be limited re-collaring opportunities each year (Antaya et al., 2024b).

If the collar is too tight, the collar could cause injury (e.g., abrasions, lesions). In the worst-case scenario, a collar that is too tight could choke the animal. This is very unlikely to happen because the issue would be noticed immediately upon collaring and adjusted. It is important to note that the safety breakaway is designed only for a sudden force applied to the collar such as an animal getting caught on a tree or other object and pulling back to attempt to free itself.

The circumference of an animal’s neck may fluctuate over time. Consider how the individual’s BCS, physiological state, and weight may fluctuate between collaring events. During collaring, it may be possible to make some slight adjustments to collar size by anticipating changes in BCS. For example, during lactation or low forage quality periods, cattle are expected to lose some weight, and collars could be fitted slightly tighter. Alternatively, the collar could be fitted slightly loose when cattle are going to gain weight (e.g., during the growing season when the forage quality is high). However, these adjustments should be made carefully to avoid putting collars on that are too tight or too loose at the time of collaring. Most VF vendors recommend visually checking on growing animals, such as heifers and steers, every 6 to 8 weeks to make sure that the collar fit is still within safe limits. Most vendors do not mention resizing for mature animals because the collar fit should be correct for them. On extensive rangelands, this might be very difficult to do because of handling facilities and grazing management plans. In addition, on rangelands and forest lands, livestock can be hard to find efficiently due to pasture size, shrubs, trees, and topography (Bailey, 2016; Bailey et al., 2021).

Figure 3. Examples of collar fit. A collar properly fit can be pulled to the top of the animal's head until it struggles to go over one ear. A collar is too loose when the collar can be pulled over both ears. Collar fitting instructions are different for each VF company.

Summary

VF systems require livestock to wear a VF collar to influence movement and distribution with a combination of auditory and electrical cues. While collar designs vary between vendors and versions, most collars include housing, metal chains or belt-like design with a bridge or a strap, and a power source (either replaceable single-use batteries or solar rechargeable batteries). Collectively, these components store electronics, help deliver the auditory and electrical cues, connect the two ends of the chains or belt-like design, and serve as the breakaway mechanism for animal safety.

Preparing for a collar deployment ahead of time is critical for success on the day of collaring. Gather and prepare all collar components prior to the collaring event. Make sure that solar-powered collars are fully charged and that replacement collars are available to manage the entire herd appropriately. Ensure that there are proper working animal handling facilities such as corrals, a lane, and a squeeze chute with a head gate. It is also beneficial to consider the timing of a collaring event in relation to the grazing management plan and other livestock management tasks. Other recommendations are to check the weather forecast, assemble the necessary tools, and gather livestock prior to collaring. Always carefully review the training materials from the VF vendor in addition to reviewing available tutorial videos and recruiting someone with previous experience to help during the collaring event (if possible).

Collaring animals can be dangerous when an unknown object is placed around their neck for the first time. To ensure human and animal safety, we recommend using low-stress livestock handling methods. This includes using a squeeze chute, positioning one person on either side of the animal, avoiding leaning or standing over the animal while collaring, and staying clear of the animal’s path when they are released from the squeeze chute. Each team works differently so it is necessary to identify the most efficient and effective way of collaring the herd with that specific workforce. People that are used to collaring together are likely more effective than when new team members are being trained.

When VF collars are properly fitted on an animal, they should be able to move around a ranch without issue. It is essential to ensure the collars are not too tight or too loose on livestock, which could injure the animal or waste time and money. When livestock wear properly fitted collars, it is time to train them with the VF technology by recognizing and interpreting the VF cues (Mayer et al., 2024). While a VF system can potentially enhance livestock distribution and rangeland management across vast areas, livestock producers should carefully research the technology because VF itself might not meet the needs for some livestock operations or objectives.

Another factsheet will cover some of the collar deployment differences between the four VF companies available in the United States as of April 2025.

Disclaimer

There are several companies that manufacture hardware and software including eShepherd™ from Gallagher™, Halter™, Nofence™, and Vence™ from Merck Animal Health™. Virtual fencing components from different manufacturers are generally not interoperable or interchangeable. Specific components, GIS data needs, software protocol, software training, frequency and duration of the cues, GPS error, livestock collaring, and livestock training protocols may vary depending on the manufacturer. Follow the manufacturer’s recommendations and guidelines. The University of Arizona does not endorse a specific product

Any feedback with your personal experience or reactions to the virtual fence technology would be appreciated and might be helpful in revising this document for future users.

Acknowledgements

This material is based upon work that is supported by the National Institute of Food and Agriculture, U.S. Department of Agriculture, under award number 2021- 38640-34695 through the Western Sustainable Agriculture Research and Education program under project number WPDP22-016. USDA is an equal opportunity employer and service provider. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture.

This work is supported by the AFRI Foundational and Applied Science Program: Inter-Disciplinary Engagement in Animal Systems (IDEAS) [Award no. 2022-10726] from the USDA National Institute of Food and Agriculture.

Additional funding for the University of Arizona’s Virtual Fence program was provided by Arizona Experiment Station, the Marley Endowment for Sustainable Rangeland Stewardship, Arizona Cooperative Extension, and The Nature Conservancy.

Visit Rangelands Gateway for additional information about virtual fencing.

References

Antaya, A.M., Dalke, A., Mayer, B., Noelle, S., Beard, J., Blum, B., Ruyle, G., Lien, A., 2024. What is virtual fence? Basics of a virtual fencing system (No. az2079). University of Arizona Extension Publication az2079, Tucson, Arizona, USA. http://hdl.handle.net/10150/672946

Antaya, A., May, T., Burnidge, W., Mayer, B., Audoin, F., Noelle, S., Blum, B., Blouin, C., Lien, A., Dalke, A., 2024. Foundations of Virtual Fencing: Strategies for Collar Management (No. az2095). University of Arizona Extension Publication az2095, Tucson, Arizona, USA. http://hdl.handle.net/10150/675677

Bailey, D. W., 2016. Grazing and animal distribution. Animal Welfare in Extensive Systems, eds J. J. Villalba and X. Manteca (Sheffield: 5M Publishing), 53–77.

Bailey, D.W., Trotter, M.G., Tobin, C. and Thomas, M.G., 2021. Opportunities to Apply Precision Livestock Management on Rangelands. Frontiers in Sustainable Food Systems, 5, 611915. https://doi.org/10.3389/fsufs.2021.611915

Ehlert, K.A., Brennan, J., Beard, J., Reuter, R., Menendez, H., Vandermark, L., Stephenson, M., Hoag, D., Meiman, P., O’Connor, R.C., Noelle, S., 2024. What’s in a name? Standardizing terminology for the enhancement of

research, extension, and industry applications of virtual fence use on grazing livestock. Rangel. Ecol. Manag. 94, 199–206. https://doi.org/10.1016/j.rama.2024.03.004

Keshavarzi, H., Lee, C., Lea, J. M., & Campbell, D. L. M., 2020. Virtual Fence Responses Are Socially Facilitated in Beef Cattle. Frontiers in veterinary science, 7, 543158. https://doi.org/10.3389/fvets.2020.543158

Mayer, B., Dalke, A., Antaya, A., Audoin, F., Beard, J., Noelle, S., Ruyle, G.B., Lien, A.M., 2024. Foundations of Virtual Fencing: Training and Animal Welfare (No. az2088). University of Arizona Extension Publication az2088, Tucson, Arizona, USA. http://hdl.handle.net/10150/672954

Mayer, B., Dalke, A., Antaya, A., Audoin, F., May, T., Blum, B., Noelle, S., Beard, J., Blouin, C., Lien, A., 2024. Foundations of Virtual Fencing: Exploring the Complexities and Challenges (No. az2089). University of Arizona Extension Publication az2089, Tucson, Arizona, USA. http://hdl.handle.net/10150/675682

Stookey, J. M., and Watts, J. M., 2014. Low-stress restraint, handling and sorting of cattle. Livestock Handling and Transport, 4th edition, 65-76. https://doi.org/10.1079/9781780643212.0065