Across the Western United States, ranchers and land managers rely on thousands of miles of physical wire fencing to manage livestock on extensive rangelands and pastoral systems (Hayter, 1939). This type of fence has improved rangeland condition in many places by allowing the creation of managed grazing systems (Holechek et al., 2011). However, physical fences can fragment landscape connectivity, pose a risk to wildlife, and impose major financial investment on land managers and producers (Jakes et al., 2018). Physical fences also provide little to no flexibility to implement adaptive management strategies (e.g., adjust pasture size, manipulate grazing distribution, avoid sensitive habitat) within a given pasture (Holechek et al., 2011). As a result, physical fences can restrict adaptive grazing management.

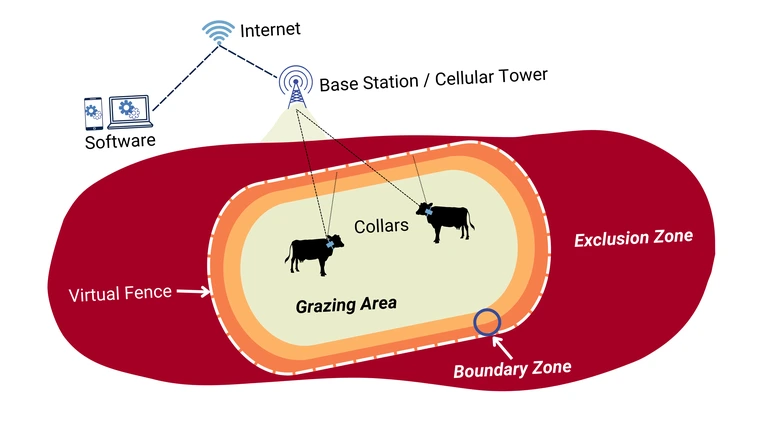

Virtual fence (VF) is an emerging precision livestock management technology which may address these limitations and potentially increase management flexibility and adaptive capacity to changing environmental conditions as part of a larger grazing management system (di Virgilio et al., 2018; Lima et al., 2018; Trotter, 2010). VF uses invisible barriers established with Global Positioning System (GPS) coordinates that influence livestock movement with a combination of auditory and electrical cues (i.e., beeping sounds, electrical pulses) (Ehlert et al., 2024). The primary elements are shown in Figure 1 and include: (1) a software interface to draw VF lines and the boundary zones on a digital map, which define the grazing area and exclusion zone; (2) a GPS-enabled collar fitted around an animal’s neck that contains technology to track livestock movement and deliver auditory and electrical cues to influence livestock distribution; and (3) base stations and/or cellular towers to transmit and receive communication between the software and collars (Antaya et al., 2024a; Ehlert et al., 2024).

VF systems hold great promise on extensive rangelands when livestock are properly trained to respond to the auditory and electrical cues generated from the collar (Mayer et al., 2024). However, the potential benefits are difficult to achieve without effort to properly manage VF collars from start to finish. This may involve labeling VF collars with a unique number, pairing the unique collar number with the individual animal number or ID in the VF system’s software, monitoring each collar, grouping collars in the VF software, locating and retrieving dropped collars, and responsibly disposing of collars at the end of their lifecycle. As a result, collar management is likely a daily task. When properly managed, VF collars allow land managers to remotely monitor livestock in near-real time and potentially gain insights into animal behavior and welfare.

This publication is part of the Foundations of Virtual Fencing series. Other titles in this series include:

- Basics of a Virtual Fencing System

- Training and Animal Welfare

- The Vital Role of High-Quality Data

- Exploring the Complexities and Challenges

- Strategies for Collar Management

- Collar Deployment Basics

- Economics of Virtual Fencing

- Watch virtual fencing videos on Rangeland Gateway

Figure 1: Conceptual model of hardware and software used to draw a virtual fence (VF) line and define the grazing area, boundary zone, and exclusion zone.

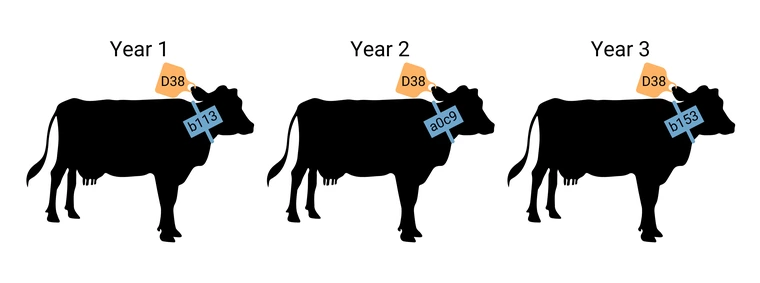

Collar identification

During collar deployment, depending on the specific vendor used, it is recommended that land managers label the front and back of the collar with the last four digits of the collar’s unique identification number (i.e., serial number) in large letters. This is best accomplished with a permanent marker or paint pen that is specifically designed for marking cattle ear tags (e.g., Z-Tag marker). This unique collar number can then be matched with the individual animal number (e.g., ear tag) in the VF system’s software. Labeling collars and pairing the collar identification number with ear tag numbers helps to identify, track, and monitor individual animals remotely through the VF system’s software. It is frequently the case that a single collar is reused on different animals from one year to the next (Audoin et al. 2024, in review) (Figure 2). When this is the case, the collar number and animal identification number must be updated and paired in the VF system’s software.

Figure 2: One animal with a unique animal identification number (e.g., D38) may be associated with multiple collars (e.g., b113, a0c9, b153) over multiple years. Updating the collar identification number each year in the VF system’s software is necessary to identify, track, and monitor individual animals remotely.

Organizing collars into virtual herds

When using VF technology in a livestock production system, managing collars in the VF system’s software can be complex. Regardless of the collar design or manufacturer, it is likely that some number of collars will fail, fall off, or lose power over time. When this happens, both functional and non-functional collars are displayed, making for a crowded and more confusing visualization of the herd in the VF system’s software. Additionally, it becomes difficult to know which collars are actively managing livestock, which could limit the usefulness of the VF system.

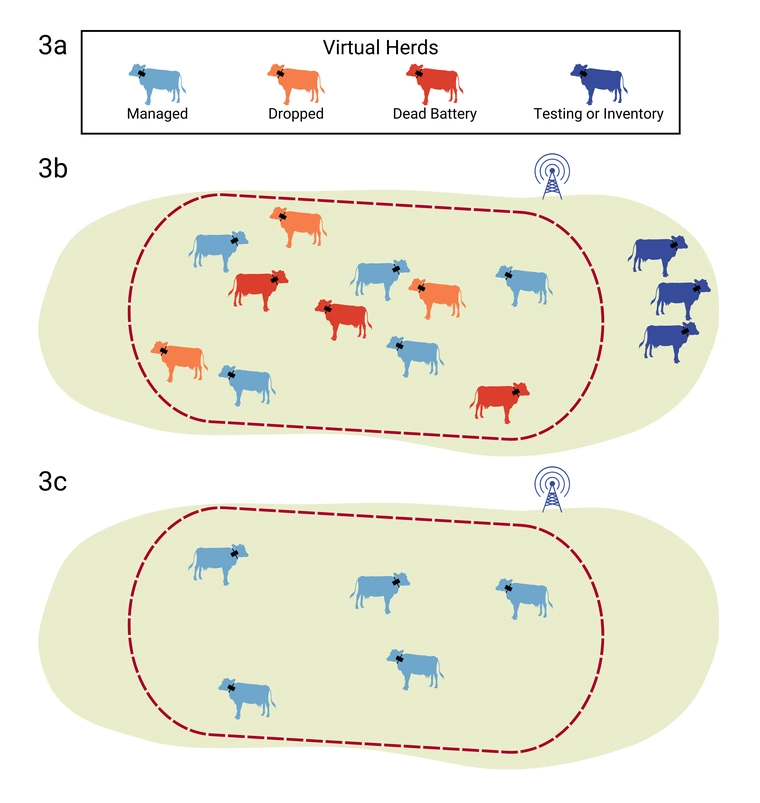

Separating collars into multiple virtual herds (i.e., digital groups of collars in the software) based on the function or status of an individual collar is one strategy for managing large quantities of collars (Figure 3a). When used, all virtual herds can be shown in the VF system’s software (Figure 3b). There are many options for types of virtual herds including managed, dropped, dead battery, testing, inventory, and safety (Table 1). For example, a collar with a functioning battery that has not moved for over 24 hours likely has fallen off the animal and is on the ground. More rarely, it may be an indicator that the animal may be sick, injured, or dead. Functioning, non-moving collars can be digitally grouped into a “dropped” collar virtual herd in the VF system’s software. The “dropped” and other virtual herds can be managed separately and turned off in the VF system’s software (Figure 3c). While the functionality of virtual herds may vary between VF vendors, they can help declutter the software interface, making it easier to visualize the portion of the “managed” herd with properly functioning, moving collars.

Moving collars into virtual herds based on their function or status helps keep an organized VF system and keeps the VF system’s software interface tidy. Successful collar management may also provide greater insights into grazing patterns, compliance (i.e., an animal’s willingness to stay within a grazing area), and potentially unusual behavior of the managed herd. Proactive collar management requires frequent attention and maintenance. It is recommended that land managers allocate approximately 15 minutes per day to review each collar’s movement in the software and assign collars to the most appropriate virtual herd. The exact daily effort may vary depending on many factors (e.g., herd size, complex topography, vegetation type) and across seasons and years.

When the managed virtual herd is clearly displayed on an accurate map in the VF system’s software, VF technology allows land managers to check the location of livestock remotely multiple times per day in near-real time (i.e., a delay of minutes to hours) (Antaya et al., 2024b). Near real-time location information can be used to monitor if livestock are in the correct pasture, locate escaped animals, and identify irregular movement over time that may warrant further investigation. Proper collar management may also allow a land manager to remotely monitor and respond to situations (e.g., no movement, calving) based on the location of a specific animal.

Figure 3. (3a) Organizing collars into multiple virtual herds based on the function or status of an individual collar (e.g., managed, dropped, dead battery, testing). (3b) All collars from all virtual herds can be shown in the VF system’s software. (3c) One or more virtual herds can be turned off in the VF system’s software, which makes it easier to visualize the portion of the herd with properly functioning, moving collars, labeled as “managed.”

Table 1: Several types of virtual herds that could be created in the VF system’s software to help keep the VF system organized and the VF system’s interface tidy.

Virtual herd types | Function or status |

Managed | Properly functioning, moving collars. |

Dropped | Collars with working batteries that have likely fallen off the animal and are on the ground. |

Dead battery | Non-functional collars that have lost power and may or may not be on animals. |

Testing | Collars being tested for functionality before deployment. |

Inventory | Spare, functional collars that are not currently on an animal. |

Safety | Collars that are kept in a truck or saddlebag and used for tracking the location of rangeland staff while in remote areas. |

Retrieving dropped collars

Land managers should anticipate that a percentage of VF collars, much like an ear tag, will fall off animals each year. The rate of dropped collars will likely vary depending on the terrain, vegetation type, physiological status of each animal, and collar manufacturer and design. The rate may be higher in rangelands dominated by shrubs or short trees than in rangelands dominated by grasses. Collars are more likely to get caught on branches and break away to prevent injury to livestock. Dropped collars can result in significant expense, both in the cost of the collar, and in the time needed to retrieve the collar. It may require a few hours per month on extensive rangelands, where lost collars may be difficult to locate. Retrieval of lost collars for repair, redeployment, or replacement is essential to managing a VF system and to limiting the cost of purchasing additional collars.

There are several potential strategies for retrieving dropped collars. Many VF vendors have included features on their collars to make them easier to find, including high contrast colors (e.g., bright orange), a sound played on command, a flashing light on the collar, or Bluetooth connection to a mobile device when the device is close to a collar (~100 ft or 30 m). Some vendors only provide the last reported GPS location for a dropped collar. In this situation, the University of Arizona has developed an ad hoc procedure that may assist with locating and retrieving dropped collars (Table 2).

Table 2: Steps for creating a virtual fence (VF) to assist with locating dropped collars that are functional but have fallen off animals and need to be retrieved. VF collars inside the auditory cue area of the boundary zone make sound, which make them easier to locate in dense vegetation.

Retrieving dropped VF collars | |

1 | Move functioning, non-moving collars into a “Dropped” virtual herd. |

2 | Create a VF boundary zone that encompasses the “Dropped” virtual herd based on the last reported location of each collar. If a single VF cannot encompass the entire “Dropped” virtual herd, create multiple fences and boundary zones. |

3 | Disable the electrical cue for the “Dropped” virtual herd. |

4 | Increase the width of the auditory cue boundary zone (i.e., 0.6 mi or 1 km). |

5 | Schedule the VF to turn on and off during a period you will be actively looking for collars in the field. This will conserve battery power. If collars run out of battery, they may be difficult to locate. |

6 | Upload the VF at least three days prior to retrieval. Dropped collars are often on the ground and not in an optimal position to receive radio or cellular signals. |

7 | Visit the pasture with the VF active and move around listening for the auditory cue to locate and collect the dropped collars. |

Battery life and disposal

VF collars generally come with either non-rechargeable batteries or batteries that are recharged by solar panels integrated into the collars. Non-rechargeable battery life is influenced by several factors, such as how often an animal interacts with a VF and how often the collar reports a GPS location. High stocking density and smaller pastures may increase interactions with VF boundary zones, resulting in shorter battery life. Non-rechargeable batteries require replacement approximately every six months or more frequently, as needed. For solar powered collars, the amount of available sunlight, shade, and weather conditions may influence battery life. The replacement period will likely depend on factors such as the collar design, vegetation structure (e.g., canopy cover), and the intensity of management using VF.

Like most electronic devices, all VF collars will eventually reach the end of their lifecycle and should be disposed of properly. Collars should not be disposed of in a landfill (i.e., regular trash) because they contain Printed Circuit Boards (PCBs) which contain heavy metals (e.g., lead, copper, zinc), and trace amounts of precious metals (e.g., gold, silver) (Bizzo et al., 2014). Local recycling facilities that specialize in recycling electronics may be able to properly recycle non-functional collars. If local recycling facilities do not exist, depleted batteries are a fire hazard and should be stored in a safe area until they can be properly recycled. Follow the manufacturer’s instructions for proper disposal.

Summary

VF systems have the potential to improve livestock and rangeland management on expansive rangelands, but they also require careful management of VF collars to achieve the greatest benefit. Best practices for collar deployment include labeling all collars with a unique number and pairing that number with an individual animal’s identification ear tag number. Without this, specific animals cannot be properly identified and managed in the VF system’s software. Best practices for managing collars in the VF system’s software include organizing individual animals with functioning collars into a “managed” virtual herd based on the paired collar and ear tag number, and organizing collars into virtual herds based on the function or status of the collar as individual collars are lost or stop functioning. Doing so will improve the visualization of VF collars in the system’s software.

Following these best practices provides numerous benefits. For example, real time tracking of livestock may be easier with VF in large pastures, over rugged terrain, after a weather event (e.g., flood), or a disturbance that damages physical fences (e.g., fire, cut wire) (Bailey et al., 2021). The ability to frequently and remotely monitor livestock in near-real time helps ensure livestock are in the correct location and helps with the retrieval of escaped animals. Proper collar management helps identify and retrieve dropped collars. Given the cost of individual collars, dropped collars should be retrieved to be replaced, redeployed, or repaired. While the VF vendor may have specific strategies for locating collars, there are also creative solutions such as scheduling a large auditory cue boundary zone so dropped collars can be heard in dense vegetation. Depending on the rate of dropped collars, land managers should anticipate spending a few hours each month retrieving dropped collars. It may be possible to pair collar retrieval with regular ranch activities to save time. Once a collar has reached the end of its lifecycle and is no longer functional, collars must be disposed of properly through an electronic recycling center or according to the manufacturer’s instructions.

When there are strategies in place to successfully manage the collars from start to finish, VF technology has the potential to help land managers by providing the ability to remotely monitor livestock in near-real time and gain valuable insights into animal behavior and welfare.

Disclaimer

There are several companies that manufacture hardware and software including eShepherd™ from Gallagher™, Halter™, Nofence™, and Vence™. Virtual fence components from different manufacturers are generally not interoperable or interchangeable. Specific components, GIS data needs, software protocol, software training, frequency and duration of the cues, GPS error, livestock collaring, and livestock training protocols may vary depending on the manufacturer. Follow the manufacturer’s recommendations and guidelines. The University of Arizona does not endorse a specific product.

Acknowledgements

This material is based upon work that is supported by the National Institute of Food and Agriculture, U.S. Department of Agriculture, under award number 2021- 38640-34695 through the Western Sustainable Agriculture Research and Education program under project number WPDP22-016. USDA is an equal opportunity employer and service provider. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture.

This work is supported by the AFRI Foundational and Applied Science Program: Inter-Disciplinary Engagement in Animal Systems (IDEAS) [Award no. 2022-10726] from the USDA National Institute of Food and Agriculture.

Additional funding for the University of Arizona’s Virtual Fence program was provided by the Arizona Experiment Station, the Marley Endowment for Sustainable Rangeland Stewardship, Arizona Cooperative Extension, and The Nature Conservancy.

For additional information about virtual fence, visit:

References

Antaya, A.M., Dalke, A., Mayer, B., Noelle, S., Beard, J., Blum, B., Ruyle, G., Lien, A., 2024a. What is virtual fence? Basics of a virtual fencing system (No. az2079). University of Arizona Extension Publication az2079, Tucson, Arizona, USA. https://extension.arizona.edu/sites/extension.arizona.edu/files/pubs/az2079-2024.pdf

Antaya, A.M., Dalke, A., Mayer, B., Blum, B., Beard, J., Blouin, C., Noelle, S., Ruyle, G., Lien, A., 2024b. Foundations of virtual fencing: the vital role of high-quality GIS data (No. az2087). University of Arizona Extension Publication az2087, Tucson, Arizona, USA. https://extension.arizona.edu/sites/extension.arizona.edu/files/pubs/az2087-2024.pdf

Audoin, F., A., Antaya, May, T., Burnidge, W., Mayer, B., Noelle, S. Blum, B., Blouin, C., Lien, A., Dalke, A. In review. Foundations of virtual fencing: collar deployment basics. University of Arizona Extension Publication, Tucson, Arizona, USA.

Bailey DW, Trotter MG, Tobin C and Thomas MG (2021) Opportunities to Apply Precision Livestock Management on Rangelands. Front. Sustain. Food Syst. 5:611915. doi: 10.3389/fsufs.2021.611915

Bizzo, W.A., Figueiredo, R.A., de Andrade, V.F., 2014. Characterization of Printed Circuit Boards for Metal and Energy Recovery after Milling and Mechanical Separation. Materials 7, 4555–4566. https://doi.org/10.3390/ma7064555

di Virgilio, A., Morales, J.M., Lambertucci, S.A., Shepard, E.L., Wilson, R.P., 2018. Multi-dimensional Precision Livestock Farming: A potential toolbox for sustainable rangeland management. PeerJ 6, e4867.

Ehlert, K.A., Brennan, J., Beard, J., Reuter, R., Menendez, H., Vandermark, L., Stephenson, M., Hoag, D., Meiman, P., O’Connor, R.C., Noelle, S., 2024. What’s in a name? Standardizing terminology for the enhancement of research, extension, and industry applications of virtual fence use on grazing livestock. Rangel. Ecol. Manag. 94, 199–206. https://doi.org/10.1016/j.rama.2024.03.004

Hayter, E.W., 1939. Barbed Wire Fencing: A Prairie Invention: Its Rise and Influence in the Western States. Agric. Hist. 13, 189–207.

Holechek, J.L., Pieper, R.D., Herbel, C.H., 2011. Range Management: Principles and Practices, 6th ed. Prentice Hall, Upper Saddle River, New Jersey.

Jakes, A.F., Jones, P.F., Paige, L.C., Seidler, R.G., Huijser, M.P., 2018. A fence runs through it: A call for greater attention to the influence of fences on wildlife and ecosystems. Biol. Conserv. 227, 310–318. https://doi.org/10.1016/j.biocon.2018.09.026

Lima, E., Hopkins, T., Gurney, E., Shortall, O., Lovatt, F., Davies, P., Williamson, G., Kaler, J., 2018. Drivers for precision livestock technology adoption: A study of factors associated with adoption of electronic identification technology by commercial sheep farmers in England and Wales. PloS One 13, e0190489.

Mayer, B., Dalke, A., Antaya, A.M., Audoin, F., Beard, J., Noelle, S., Ruyle, G., Lien, A., 2024. Foundations of virtual fencing: training and animal welfare (No. az 2088). University of Arizona Extension Publication az2088, Tucson, Arizona, USA. https://extension.arizona.edu/sites/extension.arizona.edu/files/pubs/az2088-2024.pdf

Trotter, M., 2010. Precision agriculture for pasture, rangeland and livestock systems, in: Food Security from Sustainable Agriculture 15th Australian Agronomy Conference, Lincoln, New Zealand.