This study was conducted at the University of Arizona, Yuma Agricultural Center, to quantify and compare the seasonal crop evapotranspiration (ETc) of organic and conventional iceberg lettuce under sensor-based and traditional irrigation scheduling, with and without biostimulant applications. The experiment, conducted in a randomized complete block design with eight treatments and three replications, used subsurface drip irrigation and near real-time soil moisture sensors to maintain soil water between field capacity (31.9%) and permanent wilting point (15.5%), with irrigation triggered at approximately 30–40% depletion of available water. Seasonal irrigation ranged from 295 to 328 mm, with sensor-based irrigation reducing total applied water by 10% compared to traditional scheduling. Seasonal ETc ranged from 217 to 261 mm, with the lowest in organic sensor-based irrigation without biostimulant treatment and the highest in conventional traditional irrigation with biostimulant treatment. Organic systems consistently exhibited lower ETc than conventional systems, indicating that organic management may offer a practical approach to conserving water in arid environments. Overall, integrating sensor-based, organic production systems with biostimulant which included multiple components, including a concentrated extract of plant-active soil organic matter components, chelating organic acids, sugars, and micronutrients such as 6% Zn and 1% Mn. These formulations are designed to work through both the soil and foliage.

Under subsurface drip irrigation, it could be an effective approach in improving water-use efficiency and promoting sustainable lettuce production in desert conditions.

Jump To:

- Introduction

- Importance of crop evapotranspiration

- Organic versus conventional production

- Soil and nutrient dynamics

- Influence on crop evapotranspiration

- Role of biostimulant

- Implications for irrigation management

- Sensor-based versus traditional irrigation scheduling

- Study objectives

- Materials and methods

- Fertilization and biostimulant applications

- Results and discussion

- Conclusion

- Acknowledgments

- References

Introduction

Water resources have always been central to human civilization, influencing the rise and decline of societies throughout history. In recent decades, global water use has increased at more than twice the rate of population growth (UN-Water, 2007). Agriculture remains the dominant user, accounting for roughly 75–80 % of global freshwater withdrawals (Wallace, 2000; Howell, 2001). In the United States, irrigated agriculture represents about 80 % of all freshwater use and nearly 90 % in arid and semi-arid regions (USDA Economic Research Service [USDA-ERS], 2017). Yuma, located in the Lower Colorado River Basin, is one of the most productive agricultural regions in the United States. Declining Colorado River supplies, multi-state allocation limits, and rising regional demand have intensified competition for irrigation water. Every summer, the desert reminds us of its challenges. With less than 3 inches of annual rainfall and high evaporative demand, (AZMET-Yuma Valley; https://azmet.arizona.edu/). The soil in Yuma Valley, Yuma, tends to lose moisture rapidly, and nutrients are often depleted or unavailable. For local growers, sustaining productivity in such conditions means finding creative ways to protect and improve soil health while using water efficiently.

The arid climate, high soil salinity, alkaline pH (>8.0), and low organic matter in Yuma soils present persistent management challenges (Mohammed, 2025). These factors often necessitate additional irrigation up to 20% to leach salts from the root zone and maintain soil productivity. Consequently, efficient and precise irrigation scheduling is a critical tool for sustaining high-value crops while conserving limited water supplies.

Importance of crop evapotranspiration

Crop evapotranspiration (ETc), or crop water use, represents the combined processes of soil surface evaporation and plant transpiration together forming the largest component of the crop water balance in irrigated systems. ETc plays a central role in irrigation scheduling, water conservation, and climate-resilient crop management. Accurately quantifying ETc allows growers to apply water when it is most needed, improving efficiency and reducing unnecessary losses to evaporation, runoff, and/or deep percolation. In Yuma’s desert environment, where potential crop evapotranspiration is high and rainfall is minimal, even small deviations in irrigation timing or application can result in water waste, soil salinity buildup, and yield reduction. Quantifying ETc under different production systems and management practices is therefore fundamental for improving irrigation efficiency and water-use sustainability

Organic versus conventional production

Lettuce production in Yuma, Arizona, occurs under highly managed irrigated systems where precision in both water and nutrient management determines yield, quality, and resource efficiency. The distinction between organic and conventional lettuce systems extends beyond fertilizer sources; it also influences soil structure, microbial activity, nutrient cycling, and ultimately plant water relations, ETc.

Soil and nutrient dynamics

In conventional systems, nutrients are typically supplied through synthetic fertilizers, which provide readily available nitrogen, phosphorus, and potassium in forms that plants can immediately absorb. This rapid nutrient availability often leads to faster canopy development, higher leaf area index, and enhanced transpiration, all of which can increase ETc, especially during the peak growth stages. However, this system may also risk higher nitrate leaching and greater sensitivity to over-irrigation, particularly in the coarsetextured or saline soils common in Yuma. In contrast, organic lettuce systems rely on natural or slow-release nutrient sources, organic fertilizers. Nutrient availability in organic systems is often slower and more variable, especially during the cool early season. This may lead to reduced vegetative vigor, smaller canopy area, and lower transpiration rates, thereby affecting ETc. At the same time, organic practices tend to enhance soil organic matter, microbial diversity, and waterholding capacity over time, potentially improving the soil’s ability to buffer against salinity and maintain more stable moisture conditions.

Influence on crop evapotranspiration

The balance between transpiration (plant-driven water loss) and soil evaporation (direct loss from the soil surface) differs between the two systems. Conventional fields often exhibit higher transpiration components due to faster canopy closure and greater stomatal activity, while organic fields may experience higher relative soil evaporation early in the season because of slower canopy establishment. These physiological and structural differences make it essential to measure and compare seasonal ETc between the two systems rather than relying on generalized crop coefficients derived from conventional management studies. In Yuma’s desert climate, where ET demand is high, these contrasts become even more pronounced (Mohammed, 2025). Understanding how organic and conventional systems partition water use between soil and plant processes allows researchers and growers to finetune irrigation strategies that maintain productivity while conserving water.

Role of biostimulant

Both systems in this study incorporated the use or absence of biostimulant (includes multiple components, including a concentrated extract of plant-active soil organic matter components, chelating organic acids, sugars, and micronutrients such as 6% Zn and 1% Mn. These formulations are designed to work through both the soil and foliage), which are microbial or biochemical agents designed to enhance plant nutrient uptake, root development, and stress tolerance. In saline and arid soils like those of Yuma, biostimulant can improve root-zone water absorption and plant physiological efficiency, potentially reducing overall ETc by enabling plants to maintain growth under milder water deficits. In organic systems, biostimulant may accelerate nutrient mineralization and strengthen plant-microbe interactions, partially compensating for the slower nutrient availability inherent to organic fertilizers. In conventional systems, they may improve nutrient uptake efficiency, leading to similar or greater yields with reduced irrigation frequency or volume.

Implications for irrigation management

The contrasting soil fertility regimes and canopy dynamics of organic and conventional systems mean that irrigation scheduling must be tailored to each system’s unique ETc profile. Applying uniform irrigation across both can lead to over-irrigation in organic plots or under-irrigation in conventional plots, resulting in inefficient water use or yield penalties. Therefore, quantifying ETc separately for organic and conventional lettuce and further distinguishing the effects of biostimulant use and sensor-based irrigation control is fundamental to developing precision irrigation strategies suited to the unique constraints of the Lower Colorado River Basin.

Sensor-based versus traditional irrigation scheduling

Traditional irrigation scheduling in Yuma often depends on growers’ experience, visual field observation, or fixed calendar-based irrigation intervals. These approaches can be effective under stable conditions, but in some cases, they cannot be accurate. As a result, traditional practices can lead to either over-irrigation, which promotes salt leaching and nutrient loss, or under-irrigation, which induces plant water stress and reduces yield.

In contrast, sensor-based irrigation management relies on near-real-time soil moisture data to guide irrigation timing and application depth. Soil moisture sensors continuously measure volumetric water content (depending on the soil moisture that is utilized) across multiple soil depths, allowing growers to track the soil’s position relative to its Field Capacity (FC) and Permanent Wilting Point (PWP).

- Field Capacity (FC) represents the maximum amount of water the soil can hold after excess water has drained, typically around 31.9% volumetric water content for Yuma’s clay loam soils.

- Permanent Wilting Point (PWP) represents the lower threshold of plant-available water, approximately 15.5% volumetric water content at the study site (Mohammed, 2025)

The optimal irrigation management strategy is to maintain soil moisture between FC and PWP, ensuring adequate water availability for plant uptake while preventing deep percolation losses and surface evaporation. In practice, irrigation was triggered when soil moisture approached a predetermined depletion threshold of approximately 30–40% of the available water capacity, depending on crop stage and root activity. This means irrigation occurred after 30–40% of the plant-available water had been depleted (or 60–70% remained in the root zone), ensuring that plants did not experience water stress while minimizing unnecessary water application (Mohammed & Irmak, 2022).

By maintaining this narrow range of soil water content, sensor-based irrigation systems help synchronize water application with actual crop evapotranspiration (ETc) demand. This alignment minimizes water stress periods and maximizes plant physiological efficiency. Over time, it allows for measurable reductions in total applied irrigation water without compromising yield or quality.

Sensor-based irrigation also enhances spatial and temporal precision in water management. The sensors detect variations in soil texture, root distribution, and water infiltration patterns, which are especially critical in heterogeneous desert soils prone to salinity and crusting. Integrating this data with drip irrigation systems ensures that each irrigation event replenishes only the volume of water actually consumed by the crop through ETc.

In the context of organic and conventional lettuce systems, adopting sensor-based irrigation offers the potential to:

- Reduce total irrigation water applied,

- Improve lettuce head uniformity and quality, and

- Stabilize ETc rates by avoiding fluctuations associated with moisture stress or excessive leaching.

In a region like Yuma, where every millimeter of applied water matters, such advances in irrigation scheduling represent a critical step toward balancing productivity and conservation.

Study objectives

FThe primary goal of this research is to develop and evaluate sensor-guided irrigation management strategies for both organic and conventional iceberg lettuce production systems under surface and subsurface drip irrigation in Yuma, Arizona. The specific objectives are to:

- Quantify and compare the seasonal crop evapotranspiration (ETc) of iceberg lettuce between organic and conventional production systems.

- Assess the impact of sensor-based versus traditional irrigation scheduling on lettuce ETc in each system.

- Determine how biostimulant applications influence seasonal ETc under organic and conventional management.

Materials and methods

Sensor-Based Irrigation (SI): Managed using soil moisture sensors (Drill & Drop Sentek probes) installed at 8 depths (5, 15, 25, 35, 45, 65, 75, and 85 cm) to monitor soil water dynamics through the root zone (Figure 3). Irrigation was triggered when soil water content approached a defined depletion threshold based on the field’s field capacity and wilting point relationship.

Experimental site description

The study was conducted at the University of Arizona, Yuma Agricultural Center in Yuma, Arizona, located in the Lower Colorado River Basin, a region characterized by arid climatic conditions with an average annual precipitation of less than 3 inches

The experimental site is classified as clay loam soil, with the following physical and chemical characteristics:

- Field Capacity (FC): 31.9% volumetric water content

- Permanent Wilting Point (PWP): 15.5% volumetric water content

- Particle Size Distribution: Sand 21%, Silt 48%, Clay 31%

- Organic Matter Content: 1.5% in the topsoil layer

- Soil pH: > 8.0 (alkaline)

The irrigation method was subsurface drip irrigation systems for both organic and conventional fields. The field was planted with iceberg lettuce (Lactuca sativa L.) on October 29, 2024, using pre-sprinkler irrigation to bring soil moisture to field capacity by applying water before planting to ensure enough moisture for seed germination and root establishment, especially when rainfall is insufficient (Figure 1). Germination occurred on November 6, 2024, and total preirrigation amounted to 183 mm, as measured by a Soiltech Wireless weather station installed at the site prior to planting (Figure 2).

Irrigation management

- Sensor-Based Irrigation (SI): Managed using soil moisture sensors (Drill & Drop Sentek probes) installed at 8 depths (5, 15, 25, 35, 45, 65, 75, and 85 cm) to monitor soil water dynamics through the root zone (Figure 3). Irrigation was triggered when soil water content approached a defined depletion threshold based on the field’s field capacity and wilting point relationship.

- Traditional Irrigation (TI): Followed grower-standard scheduling typical of Yuma lettuce production, based on field observations and fixed irrigation intervals used by local producers.

Figure 3. Installed Sentek (Drill & Drop) soil moisture sensors at the field to measure soil moisture status, salinity, and soil temperature at the Valley

Research Center, University of Arizona, Yuma Agricultural Center, Yuma, Arizona.

Ali T. Mohammed, University of Arizona, Yuma Agricultural Center

Fertilization and biostimulant applications

Conventional system

The conventional plots received 200 lbs/acre of nitrogen (N) applied as a pre-plant fertilizer. Biostimulant applications were applied via subsurface drip irrigation twice during the growing season according to standard local grower timing practices.

Organic system

The organic field received 2,000 lbs/acre of organic chicken pellets (4-4-2) prior to planting. An additional 1,800 lbs/acre of organic fertilizer (9-6-1) (Nature Safe Fertilizers, Darling Ingredients Inc.) was applied on January 8, 2025. Biostimulant was also applied via subsurface drip irrigation in the same manner and frequency as the conventional system. The biostimulant used included multiple components, including a concentrated extract of plant-active soil organic matter components, chelating organic acids, sugars, and micronutrients such as 6% Zn and 1% Mn. These formulations are designed to work through both the soil and foliage.

Measurement of soil moisture and environmental data

Soil moisture data were continuously recorded by Sentek Drill & Drop sensors, which provided real-time volumetric water content readings across the soil profile. Environmental parameters, including air temperature, relative humidity, and wind speed were measured by the on-site Soiltech Wireless weather station. These data were used to interpret seasonal evapotranspiration patterns and evaluate the performance of the irrigation scheduling treatments.

Quantification of Seasonal Crop Evapotranspiration (ETc)

Seasonal crop evapotranspiration (ETc) (mm) for iceberg lettuce was calculated from emergence to harvest using the soil-water balance equation:

P+I+U=R+D±ΔW+ETc

Where:

- P = Precipitation (mm)

- I = Irrigation water applied (mm)

- U = Upward soil moisture flux (mm)

- R = Surface runoff (mm)

- D = Deep percolation below the root zone (mm)

- ΔW = Change in soil moisture storage (mm)

- ETc = Crop evapotranspiration (mm)

This approach allows estimation of total water used by the crop during the growing season, accounting for all inputs and outputs in the soil-water system. Precipitation data were obtained from the on-site weather station, and irrigation volumes were recorded automatically by the drip system flow meters.

Experimental design

The experimental layout consisted of two primary production systems: Organic and Conventional, each occupying approximately 0.5 acre. Within each production system, eight irrigation and biostimulant treatment combinations were evaluated, resulting in a total of eight treatments, each replicated three times in a Randomized Complete Block Design (RCBD).

Organic Treatments:

- OSB: Organic sensor-based irrigation + biostimulant

- OSI: Organic sensor-based irrigation (no biostimulant)

- OTB: Organic traditional irrigation + biostimulant

- OTI: Organic traditional irrigation (no biostimulant)

Conventional Treatments:

- CSB: Conventional sensor-based irrigation + biostimulant

- CSI: Conventional sensor-based irrigation (no biostimulant)

- CTB: Conventional traditional irrigation + biostimulant

- CTI: Conventional traditional irrigation (no biostimulant)

Each treatment was managed independently with separate irrigation lines and fertilizer application systems to prevent cross-contamination between organic and conventional management practices.

The study incorporated a total of 24 experimental plots (8 treatments × 3 replications) arranged in a uniform field layout to minimize spatial variability. Each plot received water and nutrient inputs according to its designated treatment specifications.

Data collection and analysis

Soil moisture and irrigation data were continuously monitored throughout the growing season. ETc values were computed for each treatment using the water balance equation and validated with sensor readings. Lettuce growth and canopy development were recorded at key growth stages to evaluate plant water status and development. At harvest, lettuce yield and biomass data were collected to analyze the effects of irrigation scheduling (sensor-based vs. traditional), production system (organic vs. conventional), and biostimulant application on seasonal ETc.

Results and discussion

Seasonal irrigation amounts

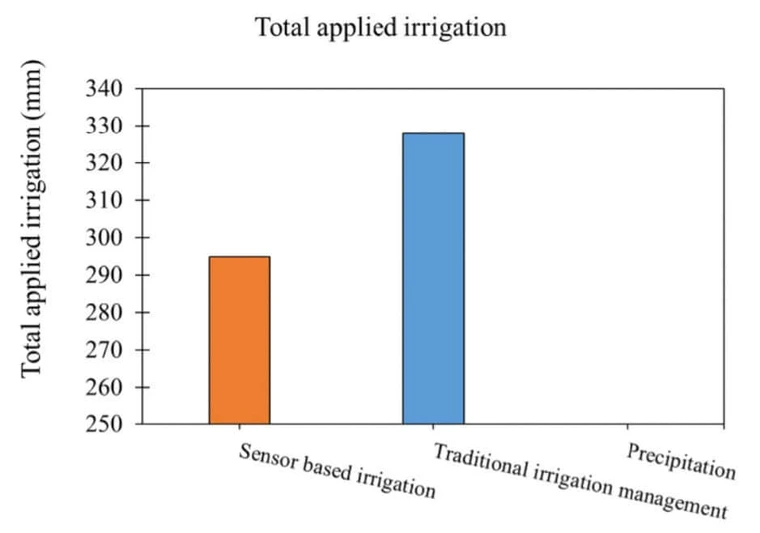

The seasonal amount of applied irrigation varied notably among treatments, reflecting differences in irrigation scheduling methods, production systems, and biostimulant use. Across both organic and conventional systems, total irrigation water applied ranged from approximately 295 to 328 mm, depending on irrigation scheduling strategy (sensor-based vs. traditional) (Figure 4). In general, sensorbased irrigation (SI) treatments consistently received less total applied water than traditional irrigation (TI) treatments within the same production system. This reduction ranged between 10%, indicating the capacity of sensor-based scheduling to minimize unnecessary irrigation events while maintaining adequate soil moisture for optimal crop growth.

Across both organic and conventional fields, irrigation events occurred six times during the 2024–2025 growing season, beginning shortly after germination and continuing at two-week intervals, with adjustments based on soil moisture data from the Sentek Drill & Drop sensors in SI plots. Traditional irrigation, by contrast, followed predetermined grower schedules typical of Yuma lettuce production.

In both systems, the slightly lower irrigation totals in the organic field compared with the conventional field can be attributed to higher soil organic matter and improved moisture retention, despite similar irrigation thresholds. The modest differences in total applied irrigation also suggest that precise soil-water monitoring may reduce the risk of overirrigation, especially in desert environments where leaching for salinity management is often necessary.

Figure 4. Total applied seasonal irrigation for sensor-based irrigation and traditional irrigation, along with the seasonal precipitation, which was zero

millimeters from planting to harvest at the Valley Research Center, University of Arizona, Yuma Agricultural Center, Yuma, Arizona.

Seasonal crop evapotranspiration (ETc)

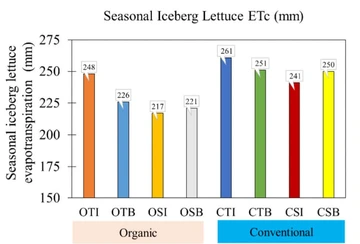

The seasonal crop evapotranspiration (ETc) of iceberg lettuce varied among irrigation strategies, production systems, and biostimulant treatments. Seasonal ETc values generally ranged from approximately 217 mm to 261 mm, consistent with recent reports for desert-grown lettuce under drip irrigation systems (Figure 5). Overall, sensor-based irrigation treatments exhibited lower ETc values compared with traditional irrigation, reflecting reduced soil evaporation and more efficient water application. The lowest ETc values were observed in the organic sensor-based irrigation without biostimulant (OSI) treatment, while the highest ETc occurred in the conventional traditional irrigation with biostimulant (CTB) treatment.

Biostimulant applications tended to increase ETc within both organic and conventional systems, likely due to enhanced root activity and canopy vigor, which in turn promote transpiration. However, the overall water-use efficiency (yield per unit of ETc) improved, indicating that the increase in ETc was associated with productive water use rather than excessive evaporation.

The organic system consistently demonstrated lower ETc values than the conventional system under equivalent irrigation scheduling, which aligns with the generally smaller canopy size, slower nutrient release, and reduced transpiration potential observed in organically managed lettuce. Conversely, conventional plots with rapid canopy closure and greater stomatal conductance showed higher ETc, especially under traditional irrigation.

Influence of irrigation scheduling and biostimulant on ETc variability

Across the experiment, sensor-based irrigation reduced seasonal ETc compared with traditional scheduling by approximately 15% with an organic system and 8% with a conventional system, highlighting the effectiveness of precision irrigation technologies in maintaining soil moisture within the optimal range between Field Capacity and Permanent Wilting Point. Biostimulant treatments also produced consistent effects across both systems. While they slightly increased ETc, this was largely associated with greater plant growth and improved physiological efficiency. This observation suggests that biostimulants may help maintain transpiration stability under moderate soil water stress, a valuable attribute in arid environments where fluctuating soil moisture can impact lettuce uniformity and quality.

Conclusion

This study quantified and compared the seasonal crop evapotranspiration (ETc) of organic and conventional iceberg lettuce under sensor-based and traditional irrigation scheduling, with and without biostimulant applications, using subsurface drip irrigation at the University of Arizona, Yuma Agricultural Center. Seasonal irrigation totals ranged from 295 to 328 mm, with sensor-based irrigation (SI) reducing total applied water by about 10% compared to traditional irrigation (TI). Seasonal ETc values ranged from 217 to 261 mm, with the lowest ETc observed in the organic sensor-based irrigation without biostimulant (OSI) treatment and the highest in the conventional traditional irrigation with biostimulant (CTB) treatment. The biostimulant used in this study contained a concentrated extract of plant-active soil organic matter components, chelating organic acids, sugars, and micronutrients (including 6% Zn and 1% Mn) designed to enhance nutrient uptake through both soil and foliar pathways. Biostimulant application slightly increased ETc within both systems due to improved physiological activity and canopy vigor, leading to greater productive transpiration rather than unproductive soil evaporation. Organic lettuce plots consistently exhibited lower ETc than conventional plots across all irrigation treatments, which suggests that organic production may offer a practical approach to conserve water under arid conditions. This lower crop water use is likely associated with slower canopy development, moderate transpiration rates, and improved soil moisture retention due to organic matter inputs. Overall, integrating sensorbased irrigation scheduling with subsurface drip irrigation (regardless of salt management) proved to be an effective and sustainable strategy to optimize water use, reduce total irrigation applied, and manage crop ETc efficiently in both organic and conventional lettuce systems. The combination of organic management and biostimulant use further supports improved water-use efficiency and demonstrates a viable pathway for water conservation and sustainable lettuce production in the Lower Colorado River Basin.

Figure 5. Seasonal crop evapotranspiration (AKA: crop water use) for each treatment under organic and conventional cropping systems at the Valley

Research Center, University of Arizona, Yuma Agricultural Center, Yuma, Arizona.

Acknowledgments

The author gratefully acknowledges the support and collaboration of the University of Arizona Cooperative Extension, the Yuma County Cooperative Extension, and the School of Plant Sciences for their support. Special thanks are extended to the staff and faculty of the University of Arizona, Yuma Agricultural Center, for their technical assistance, field management, and dedication throughout the study. The author also recognizes the contributions of Western Alliance to Expand Student Opportunities (WAESO)/ National Science Foundation (NSF) intern students for their valuable assistance with data collection, field measurements, and laboratory analysis. Appreciation is extended to Soiltech Wireless for providing weather and soil monitoring equipment and to NatureSafe Fertilizers (Darling Ingredients Inc.) for supplying organic fertilizer materials used in the organic production system.

References

AZMet. Arizona Meteorological Network (AZMet): Home. University of Arizona, College of Agriculture & Life Sciences. https://azmet.arizona.edu/ The Arizona Meteorological Network

Howell, T. A. (2001). Enhancing water use efficiency in irrigated agriculture. Agronomy Journal, 93(2), 281–289. https://doi.org/10.2134/agronj2001.932281x

Mohammed, A. T. (2025, July). Estimating crop evapotranspiration using lettuce crop coefficients for irrigation scheduling in Yuma, Arizona (az2144). University of Arizona Cooperative Extension. https://extension.arizona.edu/publication/estimating-crop-evapotranspiration-using-lettuce-crop-coefficients-irrigation UA Cooperative Extension.

Mohammed, A. T., & Irmak, S. (2022). Maize response to coupled irrigation and nitrogen fertilization under center pivot, subsurface drip and surface (furrow) irrigation: Soilwater dynamics and crop evapotranspiration. Agricultural Water Management, 267, 107634. https://doi.org/10.1016/j.agwat.2022.107634

UN-Water. (2007). Coping with water scarcity: Challenge of the twenty-first century. https://www.unwater.org/sites/default/files/app/uploads/2017/05/waterscarcity.pdf UN Water

USDA Economic Research Service. (2017, June 5). Understanding irrigated agriculture. https://www.ers.usda.gov/amber-waves/2017/june/understanding-irrigatedagriculture/ Economic Research Service

Wallace, J. S. (2000). Increasing agricultural water use efficiency to meet future food production. Agriculture, Ecosystems & Environment, 82(1–3), 105–119. https://doi.org/10.1016/S0167-8809(00)00220-6