This study investigated the effects of biostimulant application on crop growth, development, and yield of iceberg lettuce (Lactuca sativa L.) under organic and conventional production systems using subsurface drip irrigation in Yuma, Arizona. Experiments were conducted during the 2024–2025 season on a 1-acre research field equally divided into organic and conventional halves. Treatments included traditional and sensor-based irrigation scheduling, each with and without biostimulant application. Results showed that biostimulant application had little to no clear impact on plant height in organic lettuce and resulted in only slight, non-substantial improvements in the conventional system. However, the combined strategy of biostimulant and sensor-based irrigation considerably enhanced yields in the organic system, reaching up to 16.7 tons per acre. In the conventional system, this integrated approach yielded up to 27 tons per acre, comparable to other conventional treatments.

Introduction

Iceberg lettuce (Lactuca sativa L.) is a widely cultivated leafy vegetable with high nitrogen requirements, especially during the heading stage, when nutrient uptake is required to support rapid vegetative growth and large leaf biomass. In organic production systems, where synthetic fertilizers are prohibited, meeting this nitrogen demand relies strongly on organic nutrient sources. Organic iceberg lettuce, in particular, is gaining popularity locally and nationally due to increasing consumer demand for healthy, hygienic, and environmentally sustainable produce (McGrady et al., 1991; Koide & Bache, 2021). While conventional systems often utilize readily available synthetic nitrogen fertilizers to meet crop demands efficiently, organic growers face challenges in synchronizing nitrogen release with crop uptake.

Lettuce production represents a major economic sector in Arizona, and there is growing demand for input-efficient, sustainable practices. While biostimulants are increasingly marketed as tools to improve nutrient availability, root health, and overall crop resilience, evidence supporting their consistent effectiveness remains limited, especially under organic and arid production systems. Given the unique challenges in desert environments, including nutrient leaching, salt stress, and high evapotranspiration rates, biostimulant performance must be evaluated under realistic field conditions. Therefore, understanding how biostimulants perform in combination with established fertility and irrigation strategies is essential for guiding grower adoption and improving input efficiency (Rouphael & Colla, 2020; Yakhin et al., 2017).

In arid regions like Yuma, AZ, where annual precipitation is often less than 3 inches (Yuma Valley-AZMET-, 2025), extended droughts and frequent heatwaves create particularly challenging conditions for soil health and unfavorable environmental conditions for crop growth. Limited rainfall restricts natural moisture replenishment, leading to soil dehydration and reduced microbial activity, along with dry ambient microclimate, which adds further stress on crop performance. Over time, these conditions intensify soil compaction, increase salinity buildup, and accelerate organic matter decomposition, ultimately depleting essential nutrients. These factors collectively reduce soil fertility and pose significant barriers to sustaining productive organic lettuce farming without strategic efforts to enhance soil nutrient availability for plant uptake. To address this challenge, interest has grown in using biostimulants intended to enhance nutrient use efficiency and overall crop performance.

However, the effectiveness of biostimulants can be variable, depending on environmental conditions, application timing, and production system type (du Jardin, 2015). This highlights the need for localized research to evaluate their practical benefits under specific cropping and irrigation conditions, such as those in the desert Southwest. Therefore, the main objective of this investigation was to evaluate the effects of biostimulant applications on the growth, development, and yield of iceberg lettuce under organic and conventional production systems using a subsurface drip irrigation system.

Materials and methods

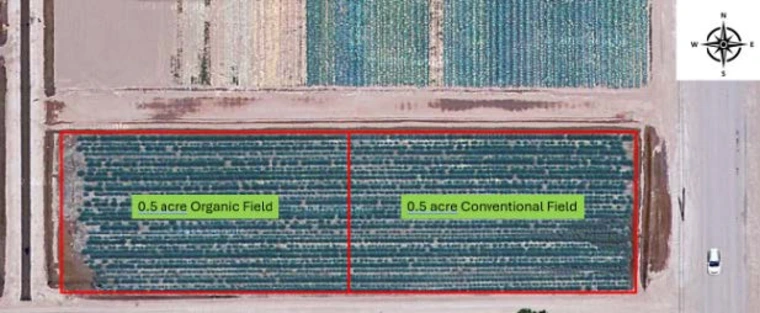

Field experiments were conducted during the fall 2024-spring 2025 growing seasons at the Valley Research Center at the University of Arizona Yuma Agricultural Center, Yuma, Arizona. This investigation was conducted on a 1-acre research field (Figure 1), divided equally into two production systems: a half-acre organic field and a half-acre conventional field.

Figure 1. Satellite image view of the 1-acre field (half-acre organic field and the other half conventional field) in the Valley Research Center at the University of Arizona, Yuma Agricultural Center, Yuma, Arizona.

Site characteristics

The experimental site is located in a region characterized by an arid climate, with average annual precipitation of less than 3 inches. The soil is classified as clay loam. Key soil physical properties include a field capacity of 31.9% (vol) and a permanent wilting point of 15.5% (vol). The particle size distribution is 21% sand, 48% silt, and 31% clay. The topsoil contains 1.5% organic matter, which reflects the low organic content typical of arid environments (Mohammed, 2025).

Irrigation, fertilizer and biostimulant treatments

Two irrigation treatments were implemented: (1) sensorbased irrigation (SI), which utilized real-time soil moisture data to guide irrigation decisions, and (2) traditional irrigation (TI), based on growers' standard practices commonly used in the Yuma area. The conventional field received a pre-plant application of 200 lbs/acre of nitrogen fertilizer. The organic field was fertilized with 2,000 lbs/ acre of chicken manure pellets (4-4-2), followed by an inseason application of 1,800 lbs/acre of organic fertilizer (9-6-1) on January 8, 2025 (Nature Safe Fertilizers, Darling Ingredients Inc.).

The experiment was arranged to compare eight treatments in total, four within the organic field and four in the conventional field, as follows:

- Organic treatments: Organic sensor-based irrigation + biostimulant (OSB), Organic traditional-based irrigation (OTI), Organic traditional-based irrigation + biostimulant (OTB), and Organic sensor-based irrigation (OSI).

- Conventional treatments: Conventional sensorbased irrigation + biostimulant (CSB), Conventional traditional-based irrigation (CTI), Conventional traditional-based irrigation + biostimulant (CTB), and Conventional sensor-based irrigation (CSI).

Additionally, biostimulants were applied through subsurface drip irrigation in both the conventional and organic fields. The first application of the biostimulant was applied on December 5, 2024, and the second application is scheduled four weeks later via a subsurface drip irrigation system.

The biostimulant used included multiple components, including a concentrated extract of plant-active soil organic matter components, chelating organic acids, sugars, and micronutrients such as 6% Zn and 1% Mn. These formulations are designed to work through both the soil and foliage.

Planting, growth measurements and harvesting

The two fields were planted on October 29th, 2024, and the pre-sprinkler irrigation strategy was utilized to ensure germination, which was noticed on November 06, 2024. Plant height was measured on November 22, 2024, and continued bi-weekly on nine plants for all treatments across the organic and conventional fields. After harvesting, the average plant height will be calculated (Figure 2). On March 3rd, both organic and conventional lettuce varieties were harvested by hand. For each treatment, a 10-foot section was harvested from a designated spot within each of the three replications. The fresh weight of the harvested lettuce was measured, and the number of plants within each 10-foot section was meticulously counted. These measurements were then scaled up to represent yield per acre and plant density per acre (Figure 3).

Figure 2. Plant height measurements in the field at the Valley Research Center at the University of Arizona, Yuma Agricultural Center, Yuma, Arizona.

Figure 3. Lettuce harvest process in the field at the Valley Research Center and weighing process in the laboratory at Yuma Agricultural Center, Yuma, Arizona.

Experiment design and analysis

The experiment was conducted using a split-split plot design with three replications for each treatment. Each experimental unit consisted of three beds, with individual beds measuring approximately 120 feet long and 3.5 feet wide. All data were compiled and analyzed using Microsoft Excel. Mean plant height and mean yield were calculated for each treatment by averaging the data across the three replications. Graphical representations were then developed to visualize the results: plant height graphs were created to illustrate growth trends and/or treatment differences. Yield bar graphs (e.g., bars) were used to compare mean yield across different treatments, and scatter plots were generated to examine the relationship between yield per acre and plant density per acre.

Results

Plant height

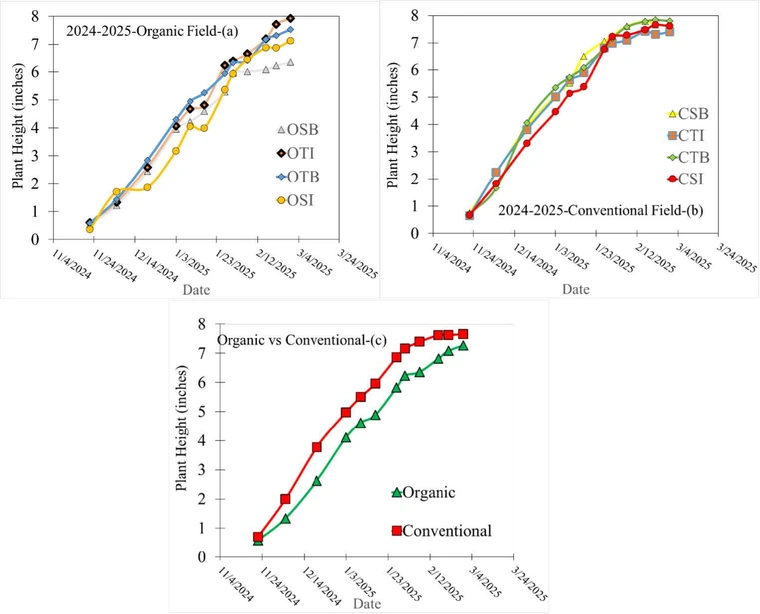

In the organic lettuce trial (Figure 4a), using a biostimulant did not lead to a clear or measurable increase in plant height. All treatments, whether they included a biostimulant or not, showed similar growth patterns, and the plants reached about the same final height by the end of the season. This suggests that, under the conditions of this study, biostimulant use did not have a strong effect on plant height in organic fields. On the other hand, in the conventional lettuce trial (Figure 4b), the tallest plants were seen in the treatments that received a biostimulant. Although these plants were slightly taller on average compared to those in treatments without a biostimulant, the differences were small and not statistically significant. Overall, while there was a slight positive trend in plant height with biostimulant use in the conventional field, the results were not statistically significant and were not strong enough to show a clear advantage. These findings suggest that the response to biostimulant use may depend on the type of production system and other growing conditions. When the data from both the organic and conventional fields were pooled together (Figure 3c), the results showed that conventional treatments generally produced taller plants than organic treatments. This indicates that lettuce grown under conventional management conditions tended to achieve greater plant height overall, regardless of biostimulant application. These findings suggest that plant response to biostimulant additions may depend on the production system and other environmental or management factors, and that the observed effects were not statistically significant under the conditions of this study.

Figure 4. Distribution of plant height: (a) Organic Field; Organic sensor-based irrigation + biostimulant (OSB), Organic traditional-based irrigation (OTI), Organic traditional-based irrigation + biostimulant (OTB), and Organic sensor-based irrigation (OSI); (b) Conventional Field; Conventional sensor-based irrigation + biostimulant (CSB), Conventional traditional-based irrigation (CTI), Conventional traditional-based irrigation + biostimulant (CTB), and Conventional sensor-based irrigation (CSI); (c) Pooled data for Organic and Conventional Field treatments. Each data point represents the average of 10 readings collected in the field at the Valley Research Center, University of Arizona, Yuma Agricultural Center, Yuma,

Arizona.

Yield

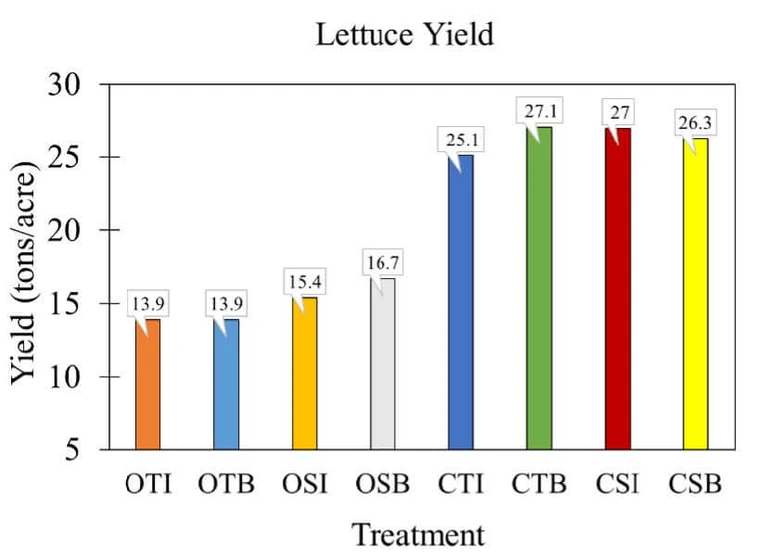

Lettuce yield results showed clear differences between organic and conventional systems, especially in how they responded to biostimulant treatments (Figure 5). In the organic field, the OSB treatment produced the highest yield, reaching about 16.7 tons per acre. While it exceeded the other organic treatments, the increase was moderate. Yields from OTI, OTB, and OSI were fairly similar, ranging from 13.9 to 15.4 tons per acre, suggesting that using biostimulant alone without sensor-based irrigation had limited benefit in boosting organic yields. On the other hand, all conventional treatments produced considerably higher yields. CTB and CSI showed the highest yields, with yields around 27.0 and 27 tons per acre, followed by CSB and CTI. These results highlight the advantages of the conventional system. The results indicated that biostimulant applications showed some extent of improvement in yield for both production systems; however, the differences were not statistically significant. In the organic field, the biostimulant-treated plots performed slightly better. Additionally, the coupled biostimulant and sensor-based irrigation strategy showed substantially higher yield in the organic lettuce system and comparable yield to other treatments within the organic lettuce system. OSB produced the highest yield at 16.7 tons per acre, which was 20% higher than OTI and OTB (13.9 tons/acre) and 8.4% higher than OSI (15.4 tons/acre); however, these differences were not statistically significant. In the conventional system, yields were generally high across all treatments, and adding the biostimulant did not result in a noticeable enhancement. These findings suggest that the biostimulant had some positive impact on lettuce yield, particularly when combined with sensor-based irrigation.

Figure 5. Lettuce yield: Organic Field: Organic sensor-based irrigation + biostimulant (OSB), Organic traditional-based irrigation (OTI), Organic traditional-based irrigation + biostimulant (OTB), and Organic sensor-based irrigation (OSI); Conventional Field: Conventional sensor-based irrigation + biostimulant (CSB), Conventional traditionalbased irrigation (CTI), Conventional traditional-based irrigation + biostimulant (CTB), and Conventional sensor-based irrigation (CSI) at the Valley Research Center, University of Arizona, Yuma Agricultural Center, Yuma, Arizona.

Relationship between plant density and yield

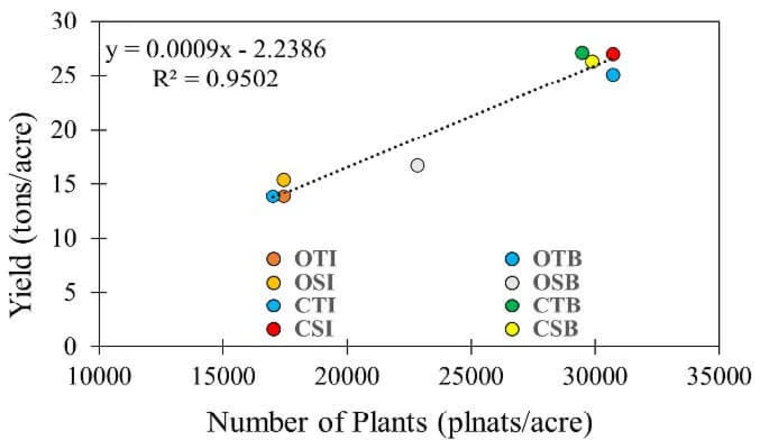

The results showed a strong positive relationship between plant population and lettuce yield across all treatments (Figure 6). As plant density increased, yield had also increased almost linearly. The high R² value of 0.9502 indicated that about 95% of the variation in yield could be explained by differences in plant population alone. CSI, CSB, and CTB had the highest plant populations at or above 30,000 plants per acre and had also achieved the highest yields, ranging from 26 to 27 tons per acre. On the other hand, OTI, OTB, and OSI had lower plant densities (below 20,000 plants per acre) and had also resulted in lower yields. Remarkably, OSB was an exception; it had a relatively high plant population but had not achieved the yield expected based on the trend line. This suggests that other limiting factors, for example, soil conditions, nutrient availability, might be influencing in reducing its performance, despite having an adequate plant stand.

Overall, the analysis highlighted plant density as a key driver of yield, particularly in conventional systems where the combination of high density and input optimization appeared to support better crop performance.

Figure 6. Lettuce yield: Organic Field: Organic sensor-based irrigation

+ biostimulant (OSB), Organic traditional-based irrigation (OTI),

Organic traditional-based irrigation + biostimulant (OTB), and Organic

sensor-based irrigation (OSI); Conventional Field: Conventional sensor-based irrigation + biostimulant (CSB), Conventional traditionalbased irrigation (CTI), Conventional traditional-based irrigation + biostimulant (CTB), and Conventional sensor-based irrigation (CSI) at the Valley Research Center, University of Arizona, Yuma Agricultural Center, Yuma, Arizona.

Conclusions

Biostimulant use had little to no effect on plant height in organic lettuce and only a slight, non-significant increase in conventional lettuce systems. When combined with sensorbased irrigation scheduling, biostimulant use may help increase yield while conserving water in organic systems and reducing both water usage and labor in conventional fields. Plant density demonstrated the strongest influence on yield, highlighting its critical role in maximizing lettuce productivity.

Acknowledgments

The authors gratefully acknowledge the support of the School of Plant Sciences and the Yuma Agricultural Center at the University of Arizona. Special thanks to the University of Arizona Cooperative Extension for their continued guidance and resources. Appreciation is also extended to the Western Alliance to Expand Student Opportunities (WAESO) for funding the internship students who contributed to this project. The project team also acknowledges the contributions of Wireless Soil Tech, AquaSpy, EarthScout, Valent BioSciences and Nature Safe Fertilizers for providing technologies and products that supported data collection and field management.

References

du Jardin, P. (2015). Plant biostimulants: Definition, concept, main categories and regulation. Scientia Horticulturae, 196, 3–14. https://doi.org/10.1016/j.scienta.2015.09.021

Koide, R., & Bache, I. (2021). Urban sustainability transitions: Bottom-up and top-down governance and the role of politics. Frontiers in Sustainable Cities, 3, 582431. https://doi.org/10.3389/frsc.2021.582431

McGrady, J., Matheron, M., Palumbo, J., Rethwisch, M., Butler, M., Matejka, J., & Tilt, P. (1991). Sustainable lettuce production. University of Arizona Cooperative Extension.

Mohammed, A. T. (2025). Soil characterization for lettuce production trials in arid regions: Field and laboratory data summary. University of Arizona, unpublished data.

AZMET. (2025). Arizona Meteorological Network. The University of Arizona. Retrieved from https://azmet.arizona.edu

Rouphael, Y., & Colla, G. (2020). Editorial: Biostimulants in Agriculture. Frontiers in Plant Science, 11, 40. https://doi.org/10.3389/fpls.2020.00040

Yakhin, O. I., Lubyanov, A. A., Yakhin, I. A., & Brown, P. H. (2017). Biostimulants in Plant Science: A Global Perspective. Frontiers in Plant Science, 7, 2049. https://doi.org/10.3389/fpls.2016.02049